BondPlus® Electrical

BondPlus®electrical tapes

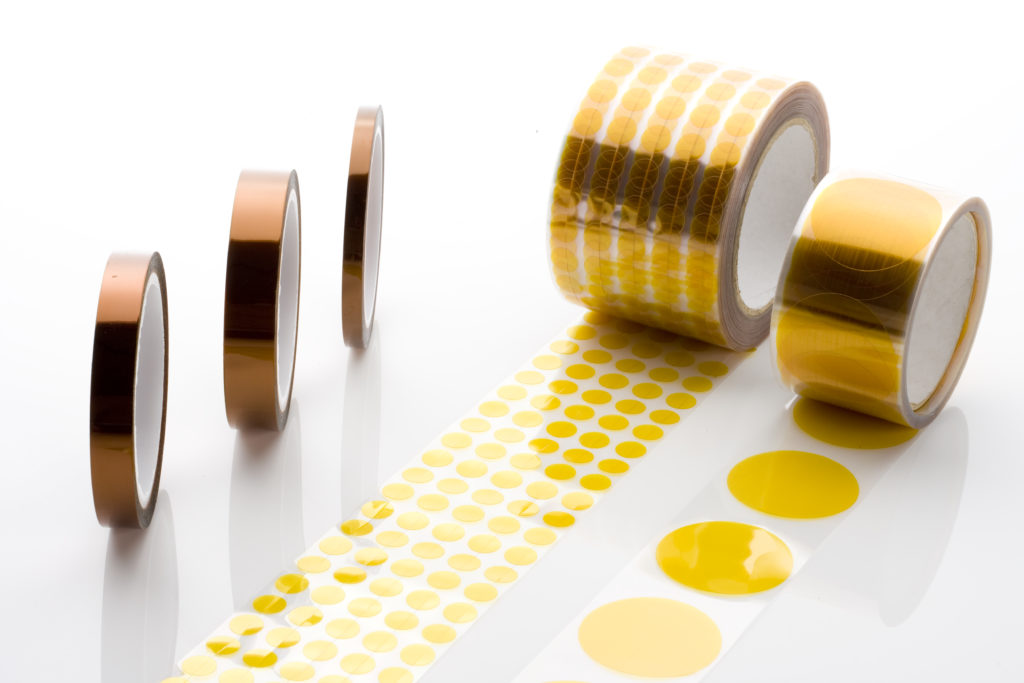

BondPlus® Tapes are high-quality technical tapes developed for a range of applications in the electronics industry, suitable for bonding, masking, shielding and surface protection.

Our products have excellent properties for the high specification demands of the electronics industry in the 21st-century.

High grade acrylic, silicone and electrically conductive adhesives are used in conjunction with the best available films and metal foils to give outstanding results for high-performance consumer electronics, avionics, industrial electronics and telecoms.

BondPlus® Electrical tapes

Applications

Electrical installation.

EMI/RFI shielding.

Anti-static applications.

PCB masking.

Bonding to high temperature surfaces.

Conductive connection and fixing.

Our BondPlus® Electrical are used in multiple applications (industries)

BondPlus® Electrical product list

| Grade | Thickness (microns) | Thickness | Format | Temperature resistance (ºc) | Special features | Data sheet |

|---|---|---|---|---|---|---|

| HB102 Silver | 50 | unsupported | –120 | Buzzbars, EMC applications, EMI/RFI Shielding, | Download | |

| HB254 Clear | 45 | single | 10–100 | Anti Static, | Download | |

| HB340 Silver | 40 | single | –110 | Conformable for curved/uneven surfaces, Electrical Conductivity, EMI/RFI Shielding, | Download | |

| HB350 Silver | 50 | single | –110 | Conformable for curved/uneven surfaces, Electrical Conductivity, EMI/RFI Shielding, | Download | |

| HB710 Silver | 85 | single | -20–130 | Buzzbars, EMC applications, EMI/RFI Shielding, | Download | |

| HB720A Copper | 65 | single | -20–130 | Buzzbars, EMC applications, EMI/RFI Shielding, | Download | |

| HB740 Copper | 65 | single | -20–130 | Buzzbars, EMC applications, EMI/RFI Shielding, | Download | |

| HB750 Silver | 110 | single | –130 | Buzzbars, EMC applications, EMI/RFI Shielding, | Download | |

| HB830 Amber | 70 | single | -20–260 | Clean removable, Electrical Insulation, Excellent chemical & electrical resistance, High Temperature Resistance, Masking, Surface protection, | Download | |

| HB830 FL Amber | 70 | single | -20–260 | Clean removable, Excellent chemical & electrical resistance, High grade silicone adhesive, High Temperature Resistance, Masking, Surface protection, | Download | |

| HB836 Amber | 50 | single | -20–200 | Anti Static, Electrical Insulation, EMC applications, Fixing electronic components, Ideal for shielding, Insulation properties, Prevents short circuits, | Download | |

| HB850 Green, red, yellow & blue | 65 | single | -20–200 | Anti Static, High grade silicone adhesive, High Temperature Resistance, Masking, | Download | |

| HB850FL | 65 | single | -20–129 | Electrical Insulation, Excellent chemical & electrical resistance, fluropolymer release liner, Insulation properties, | Download | |

| HB854A Clear | 100 | single | -20–130 | High grade silicone adhesive, High Temperature Resistance, Insulation properties, Masking, | Download | |

| HB857 DG | 80 | single | -20–200 | High grade silicone adhesive, High Temperature Resistance, Leaves no residue when removed, Masking, | Download | |

| HB857 DG FL | 80 | single | -20–200 | fluropolymer release liner, High grade silicone adhesive, High Temperature Resistance, | Download | |

| HB910A Clear | 110 | single | -20–180 | Double sided polyester, | Download | |

| HB930 Amber | 100 | double | -20–230 | Clean removable, Double sided polyester, Electrical Insulation, Excellent all round performance, Excellent chemical & electrical resistance, Fixing back light displays, Fixing electronic components, fluropolymer release liner, High grade silicone adhesive, High Temperature Resistance, Insulations of battery terminals, Masking, Prevents short circuits, Surface protection, | Download | |

| HB938A Copper | 100 | single | –130 | Buzzbars, EMC applications, EMI/RFI Shielding, | Download |