Pyro-Bond® Thermal

Pyro-Bond® Thermal Management

Hi-Bond Tapes range of thermal management tapes are of the highest quality and performance available.

As the electronics industry becomes more sophisticated and with reduction in device sizes the requirement for heat dissipation is becoming increasingly crucial for manufacturers.

Heat management for mobile phones, tablets, computers, television and all electrical devices generating heat, is necessary.

Tapes used as thermal interface materials and bonding medium are ideal for reducing hotspots and protecting sensitive circuitry and components.

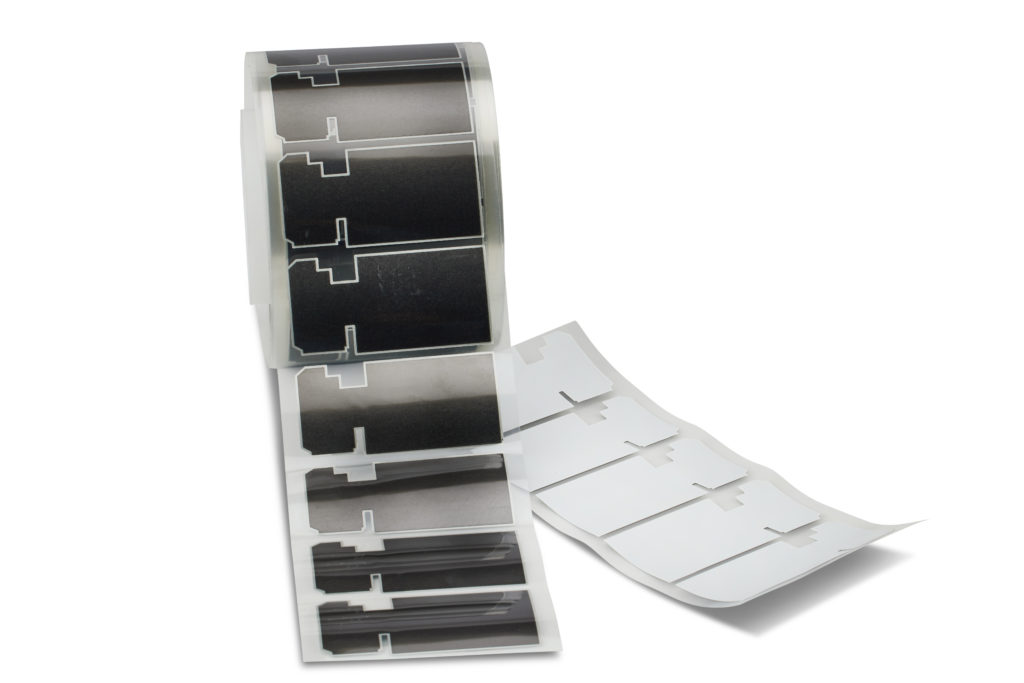

Pyro-Bond® tapes can be die-cut into precise complex shapes for intricate designs and applications, supplied as individual pieces or on rolls and sheets.

The three different categories are:

• VST® Acrylic foams which are thermal transmission bonding tapes.

• Natural and Synthetic graphite laminated with thin adhesive coated films.

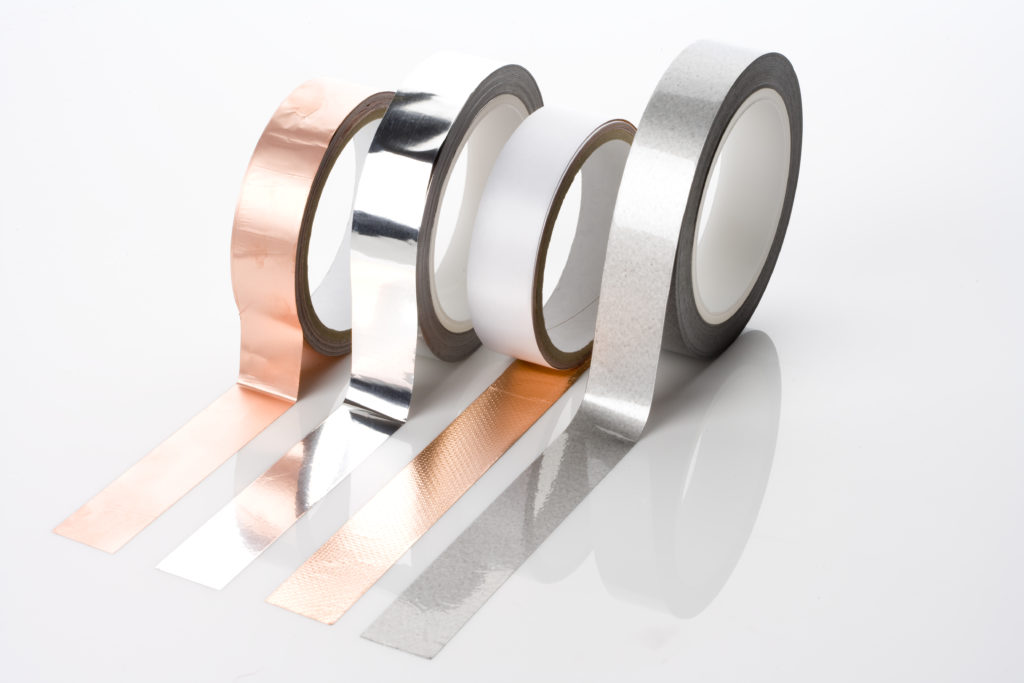

• Metal foils with thermally conductive graphite adhesive.

Our Pyro-Bond® Thermal are used in multiple applications (industries)

Pyro-Bond® Thermal product list

| Grade | Thickness (microns) | Thickness | Format | Carrier | Temperature resistance (ºc) | Special features | Data sheet |

|---|---|---|---|---|---|---|---|

| HB050TC | 50 | single | polyester | -10–120 | Fast heat spread, Ideal for shielding, | ||

| HB060TC | 60 | single | metal | -10–90 | Fast heat spread, Ideal for shielding, Very good conductivity, | Download | |

| HB160TC | 160 | single | metal | -10–90 | Excellent adhesion, Fast heat spread, Good stability, Very good conductivity, | Download | |

| PB017S | 17 | double | metal | 500– | Eliminates hot spots, Flexibility, | Download | |

| PB025S | 25 | double | metal | 500– | Eliminates hot spots, Flexibility, Thermally conductive, | Download | |

| PB030N White | 30 | single | metal | -40–160 | Eliminates hot spots, Flexibility, Halogen free, Thermally conductive, Very good conductivity, | Download | |

| PB040S Black | 40 | single | metal | –160 | Eliminates hot spots, Flexibility, | Download | |

| PB050N | 50 | single | metal | -40–160 | Eliminates hot spots, Flexibility, Halogen free, Very good conductivity, | Download | |

| PB070N | 70 | single | metal | -40–160 | Eliminates hot spots, Flexibility, Halogen free, | Download | |

| PB100N | 100 | double | metal | -40–600 | Eliminates hot spots, Flexibility, Thermally conductive, | Download | |

| PB200N | 200 | double | metal | -40–600 | Eliminates hot spots, Excellent thermal transmission, Fixing heat-sinks, Flexibility, Halogen free, High Temperature Resistance, thermal management, Thermally conductive, | Download | |

| PB450N | 450 | double | metal | -40–600 | Eliminates hot spots, Flexibility, Halogen free, UL CERTIFIED, | Download | |

| PB940N | 940 | double | metal | -40–600 | Eliminates hot spots, Flexibility, Halogen free, UL CERTIFIED, | Download |